Sample transportation is headed down the recycling road

Recycling is a major challenge for the medical and health care sector. After all, it might not always seem possible to prioritise sustainability when hygiene and therefore safety are at stake. However, it doesn’t necessarily have to be a case of choosing between these two important factors. The DEBATIN experts accepted the challenge… As a producer of packaging solutions for sample transportation, the company has introduced an innovative way to meet both sustainability and hygiene standards – simply by making it easier to start the recycling process in the laboratory itself.

This is an important milestone. After all, the healthcare sector produces at least ten times as much plastic waste as many other sectors, as reported on the website of the German Council for Sustainable Development. The report (in German) also remarks that medical laboratories (preanalytics) apparently account for some two percent of global plastic usage. At the same time, hospitals in Germany alone generate 4.8 million tonnes of waste each year (source: Statista). And 25 % of that is plastic.

Sample transportation isn’t the end of the road

“DEBATIN partners with the healthcare sector and we are a familiar name with anyone who needs to transport medical samples to the lab,” explains DEBATIN’s CEO Thomas Rose. “And we don’t just ensure our products guarantee compliance with packaging instruction P650. Sustainability is equally important to us.”

Indeed, the company is pressing forward in every sense of the word with its sustainability solution for laboratories – specifically, for recycling the plastic that DEBATIN uses to make the leakproof bags that transport samples to the lab. These bags meet international and European standards and directives for transporting infectious substances.

It’s simple. It’s compact(ed)

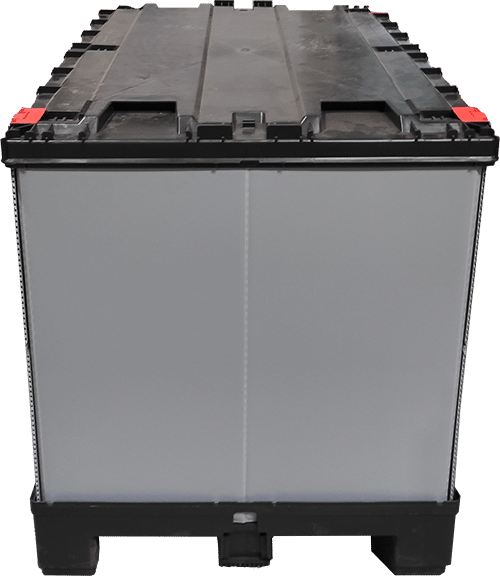

“We provide recycling balers that our customers can use in their labs, and quite a few have now taken up this offer, so that they can collect and bale their used sample bags,” explains Jörg Keilbach, process manager and sustainability officer at DEBATIN. The bales of compacted sample transport bags are collected directly from the lab by a logistics company (organised by DEBATIN) and move through the recycling loop. Thomas Rose sees this as a positive for the planet: “We’re making it possible for labs and hospitals to establish greener workflows.”

Bale, stack, and await collection!

Collect

Load

Bale

Unload

Stack

Arrange collection

Around 1200 transport bags can be fed into the baler at a time, explains Jörg Keilbach, and are then compacted into a six-kilo plastic bale. During the compaction process, the bags are heated to around 200 °C at several points, ensuring that the compacted material is fully sanitised. The bales can then be stacked into reusable boxes – also provided by DEBATIN – and certified with Germany’s Blue Angel eco-label. “All of our customers get three of these boxes, which unfold to fit a Euro-pallet,” explains Jörg Keilbach. Once two of the boxes have been filled, the customer just needs to give DEBATIN a call; DEBATIN will then notify the logistics company, who arrive to collect the filled boxes and provide empty ones in exchange. And that’s all there is to it: the sample bags are in their turn transported to the appropriate recycling centre.

Safety first – contaminated waste stays separate

Unsurprisingly, materials that are contaminated during sample transport are excluded from this optimised recycling process. Jörg Keilbach explains: “Safety comes first: these items need to be handled in a separate disposal loop.”

But that’s not the only way safety comes first with DEBATIN: “We don’t want anyone to burn their hands on the heated material. After baling and heating, a cooling process is launched, using circulating air to reduce the temperature of the recycled block until it is down to about 40° C.” Once the cooling process has finished, the machine emits a visual signal and an audible alert that the bale is ready. The process takes around 45 minutes – just one of those to load the machine, and then the lab workers can get on with other tasks while the baler handles the rest automatically.

It’s a fact: DEBAMED® products can be recycled

“The recycled material is used to make new packaging products for mailing medical samples,” explains Jörg Keilbach. “The material we use for our DEBAMED® products (e.g., DEBAMED® Speci-Sorb) can all be recycled. This has been verified and certified by recycling experts interzero, who awarded us 8 out of 12 points for recycling suitability.”

Are you interested in making your lab greener and recycling your sample bags? Try out DEBATIN’s customer-oriented solution and bale your bags so they can be sent along the road to sustainability!

Pictures of the thermal baler © A.T.M. Service B.V.