DEBAMED® Speci-Sorb gains acclaim as smart packaging for the healthcare sector

The WorldStar Award is commonly regarded as one of the world’s most prestigious packaging awards. This year, Anton Debatin GmbH won one of these coveted trophies – an accomplishment of which we’re immensely proud! It was also a very welcome pat on the back for all the sheer hard work we put in during the lead-up to the award. But first things first: let’s begin by explaining who, what, why and where…

An award that packaging companies the whole world over compete to win

The World Packaging Organisation (WPO) set up the WorldStar Award in 1970 to pay tribute to successful and smart packaging from around the world. Every year, the WPO selects the best international packaging innovations. The award aims to raise more awareness for the important role packaging plays in helping to improve lives. It also pays tribute to the best packaging innovations – those which address topical concerns such as sustainability, hygiene and other trending issues. This year, DEBATIN received a “2024 WorldStar Award” for one of its latest innovations, DEBAMED® Speci-Sorb.

DEBAMED®Speci-Sorb : effective packaging for the healthcare industry

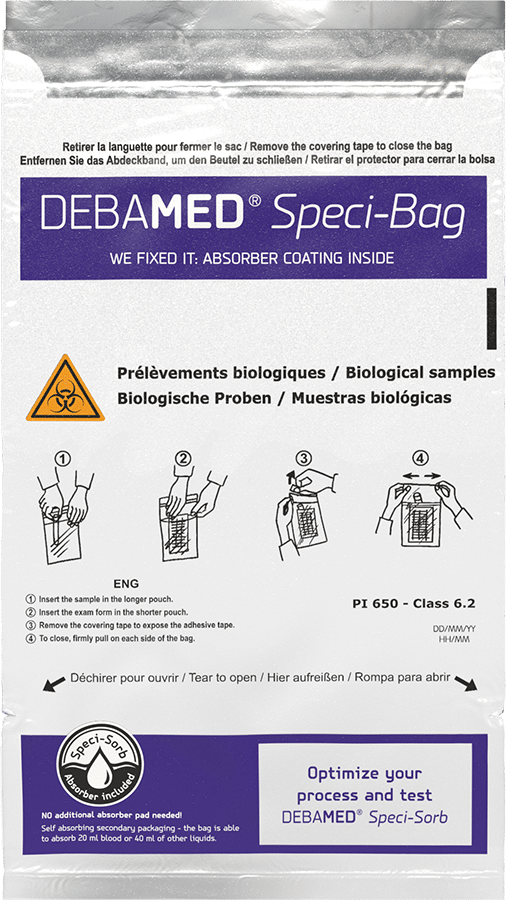

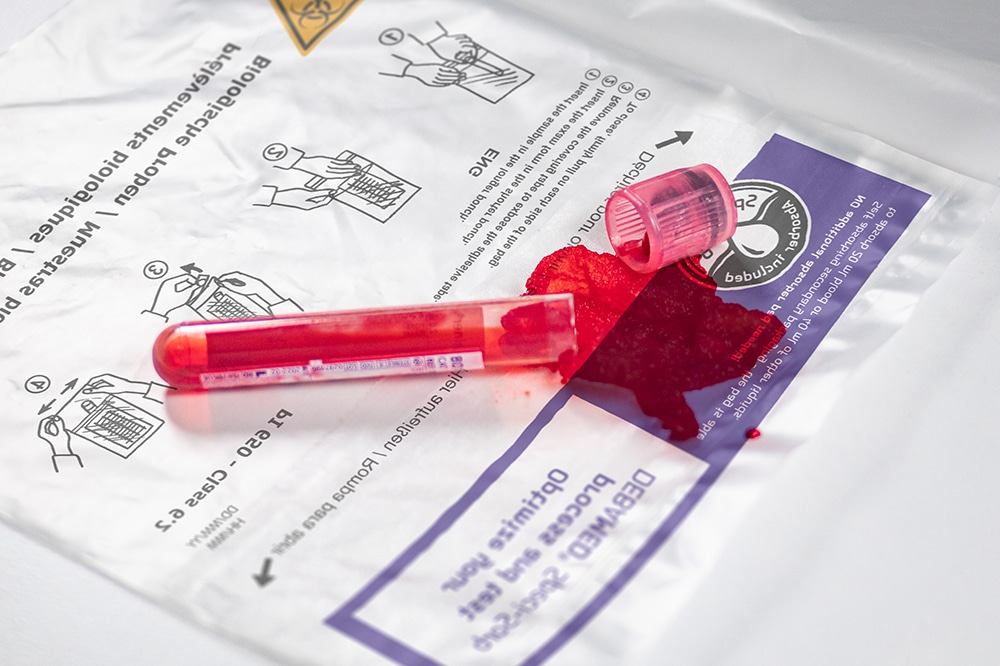

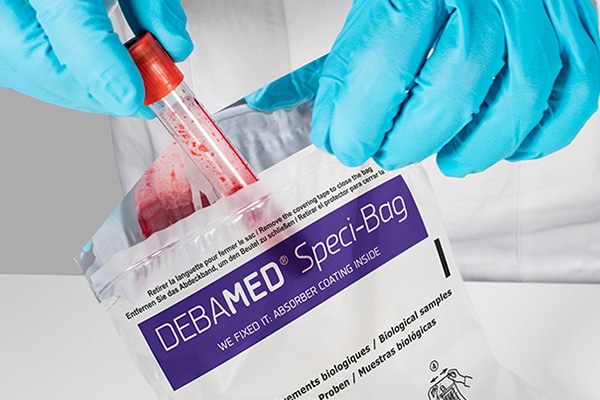

The jury, consisting of 45 international experts, praised DEBAMED® Speci-Sorb as being the most effective packaging to date for transporting medical samples without leakage and in compliance with national laws and regulations. DEBATIN’s innovation is based on an ingenious idea that finally makes the laborious task of manually adding absorbent liners to each package redundant. Instead, our production line now includes a step in which an absorbent layer is automatically integrated into the packaging. To do so, we use a special absorbent coating (patent pending).

Increasing efficiency

The key advantages of our latest innovation are twofold. Firstly, it’s more efficient for Anton Debatin GmbH’s production. And secondly, it means customers can count on a reliable supply of absorbent packaging. If a medical sample container breaks inside our innovative packaging, any hazardous substances that leak out immediately coagulate into a gel. This prevents the contamination from spreading any further. The layer with the gelling agent is integrated into the inside of the packaging. In the past, standard absorbent liners weren’t integrated as fixtures, which meant they frequently got lost – thus presenting a significant safety risk during the transit of hazardous substances.

interzero awards DEBATIN certification of recyclability

DEBAMED® Speci-Sorb is not just decidedly smart – it’s also decidedly sustainable! This claim has now been officially confirmed by the interzero Recycling Alliance, who recently awarded DEBAMED® Speci-Sorb their “Made for Recycling” certificate. In the evaluation process, we were assessed as “Good”, with 16 out of 20 points. Our Speci-Bags (without Speci-Sorb) were also certified, and scored 18 out of 20 points. The assessment criteria for this certification were developed by bifa Umweltinstitut GmbH, and the tests were conducted by the Fraunhofer Institute for Process Engineering and Packaging. Naturally, we’re delighted – but it’s great news for our laboratory customers (and future laboratory customers!) too. Why? Because 40 % of all German laboratories say sustainability is a matter of high or very high importance in their company!

An award for award-winners only

Let’s talk briefly again about the WPO. The WPO is an international alliance of national packaging institutes and associations, regional packaging associations and other interested parties such as companies and trade associations. This year, WorldStar received 435 submissions from 41 countries around the world. Based on assessments by the jury, 214 of these submissions were selected as winners of the WorldStar Award. Incidentally, not everyone can submit an entry to the WorldStar Competition. Companies can only enter if their packaging has already won a recognised national or regional award within the last year.