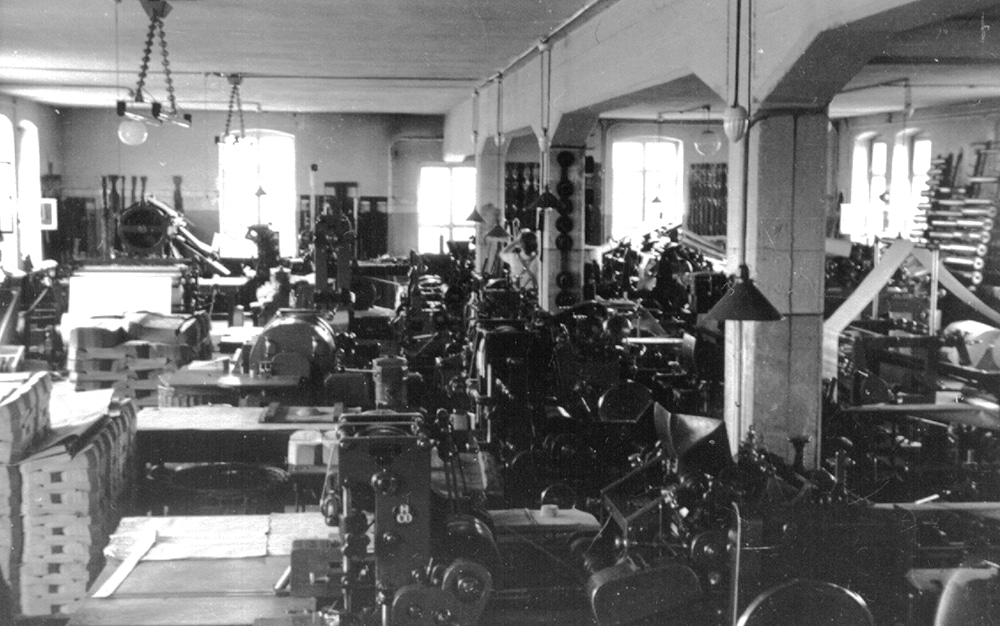

Back in 1923 when the company was founded, machinery didn’t loom large in DEBATIN’s production facility. One printing press and one typesetter were sufficient to print a variety of papers and various other small items. Paper bags of various sizes were pasted together by hand (often by homeworkers).

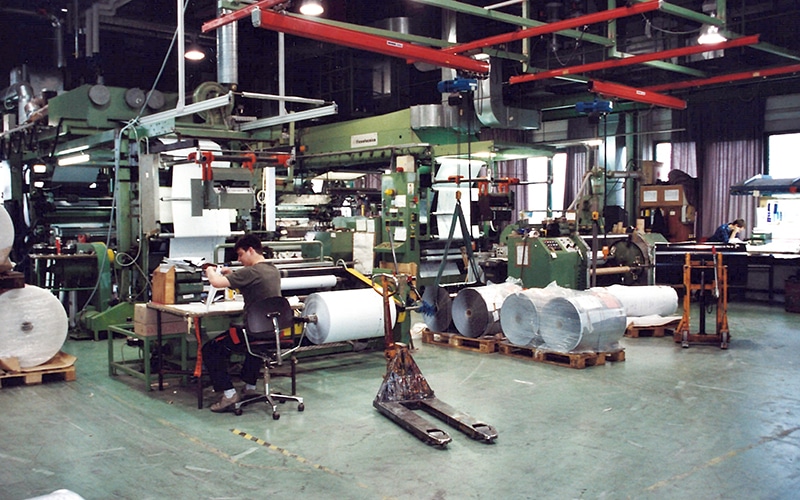

Over time, however, materials, products and requirements have change. And DEBATIN has changed with them. We have been consistently open to progress in technology and remained innovative, bold, and quick to react. When the demand rose for plastic bags in the 1960s, and when the first UNIPACK® self-adhesive document pouches were needed for the German railways in the 1970s, the problem was the same: the materials were there, and the ideas were there – but there were no machines (yet) to make the products. So DEBATIN developed its own machines. Production could then begin and demand could be met.

Technological progress: supporting and relieving workers

Over the last few decades, DEBATIN’s production systems have evolved and improved, step by step, as we’ve responded to market requirements, made efficiency improvements, standardised and harmonised, simplified recurring processes, and relieved the load on our production workers in myriad ways. By making daily tasks smoother for our team, we make opportunities for them to develop deeper professional expertise and experience, and make better use of their skills.

After all, people can do things that no machine can. It’s the unique talents that our DEBATEAM bring to the company that make the difference when it comes to truly custom solutions.

Our digital workflows and state-of-the-art machinery support our DEBATEAM, ease their daily tasks, and create space – space for creative work; space to nurture innovative ideas.

Technology, automation, and the digital revolution: transformation and opportunity

Evolution and transformation are only possible if the changes are accepted and integrated into daily life, and if opportunities are recognised and grasped. At DEBATIN, we have always kept abreast of technological progress – indeed, we’re often a step ahead. That’s what marks us out. That’s what has always been and will continue to be the basis of our innovative products and solutions.

That’s why we believe strongly in automation, digital transformation, and special-purpose equipment. And in the abilities of our DEBATEAM. After all, it’s this combination of innovative capacity, experience and technological progress that underpins our ability to identify market requirements early on, develop new products, set the standards for our industry, and keep evolving and growing.

Do you want to contribute to innovation, with a committed employer?

Are you interested in joining our DEBATEAM, making a real contribution, and working at a company that believes strongly in walking the talk when it comes to social transformation and a sustainable future?

If so, apply to us!

Contact:

Anton Debatin GmbH

HR department

Anja Westendorf

Vichystrasse 6

76646 Bruchsal, Germany

Phone +49 7251 8009 161

personalbuero@debatin.de

Current DEBATIN vacancies and apprenticeship openings at:

debatin.com/working-for-debatin/employees

debatin.com/working-for-debatin/vocational-training